Innovative Approach to Reducing Operational Costs: BIM 7D

7D Model: Digital Twin for Facility Management

7D Model Concept

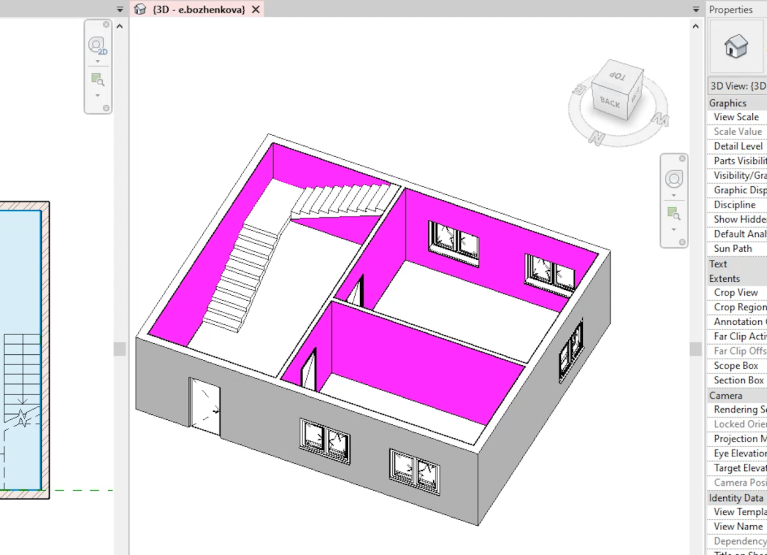

7D model is a facility management model — a digital twin of the building. It is a three-dimensional model with an integrated database of all equipment and building elements necessary for efficient operation.

Considering that 85% of building lifecycle costs are attributed to operation, this is where the greatest potential for savings lies. The solutions made at the design stage, taking into account future operation, can provide savings of 5 to 33% in operational costs.

7D Model Creation Process

To obtain a quality 7D model, it is necessary to develop a document comprising three types of requirements:

- Strategic — determining who needs the information, why, and what characteristics the information should have.

- Operational — detailing which systems and equipment in the building will be monitored

- Client information requirements for the facility management model.

Development Stages

7D model creation process embraces several key stages:

- Collection and accumulation of information with linking a 3D model to each element at design and construction stages

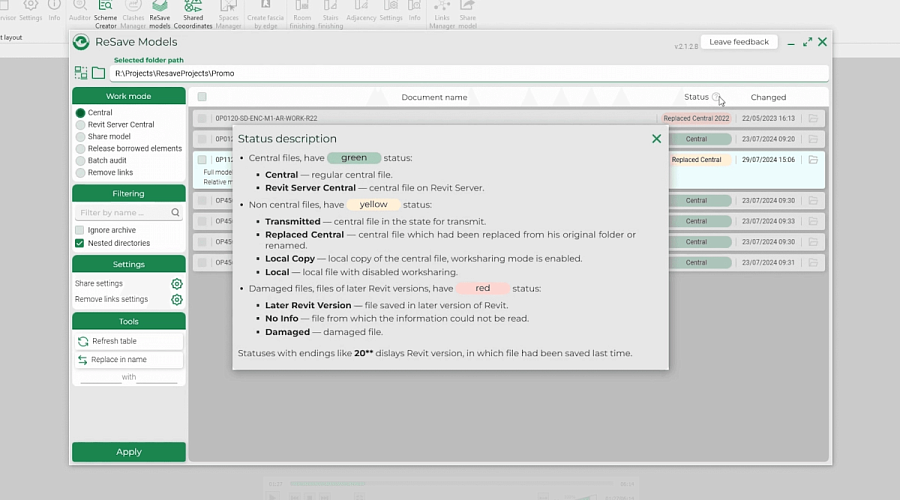

- Use of common data environment to accelerate and simplify the process

- Correction of the model according to an as-built facility

- Creation of a facility management model based on the as-built model according to client requirements

Operation Software

Various categories of software are applied to use the information from the 7D model:

- CAFM/IWMS — Computer-Aided Facility Management/Integrated Workplace Management Systems

- CMMS — Computerised Maintenance Management Systems

- ERP — Enterprise Resource Planning

- BMS/BAS — Building Management/Automation Systems

COBie Standard

To ensure compatibility with various software, it is recommended to use international COBie standard. This is a set of Excel tables, the sheets of which are divided by topics and linked to 3D model elements through unique identification numbers.

Information in 7D Model

The information in the model is structured into six main groups:

- General information

- Energy consumption management

- Maintenance management

- Space management

- Asset management

- Sensor and gauge information

Five Stages of Digital Twin Development

Depending on the scope of the integrated information, five stages of digital twin development can be singled out:

First stage — graphically correct digital twin without additional information.

Second stage — digital twin containing information about all equipment, premises, and sensors.

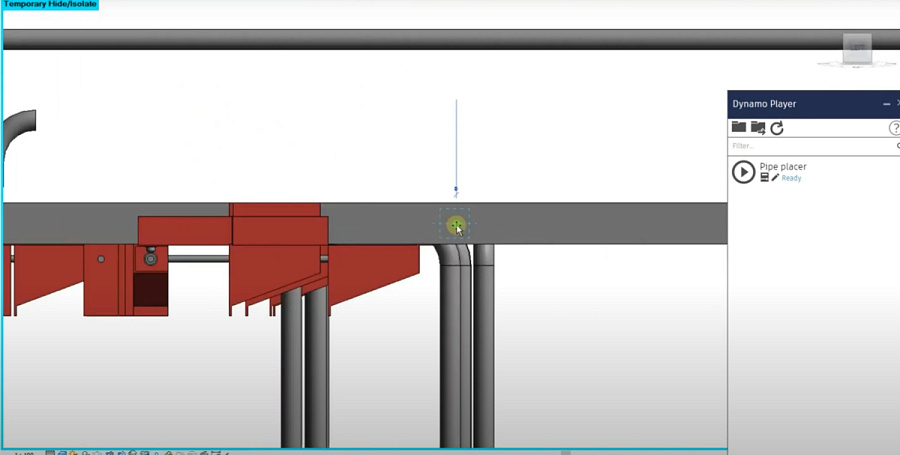

Third stage — process automation with connected sensors and monitoring devices. The system can automatically determine the necessity of maintenance, such as filter replacement, when the differential pressure is exceeded.

Fourth stage — training of the system. The software analyses the data and can automatically call maintenance specialists .

Fifth stage — digital autonomy. The system independently analyses sensor readings, their operating history, and makes decisions about necessary actions to prevent failures.

Practical Application

Practical use of the 7D model significantly simplifies operational processes.

For example, a QR code can be added to each piece of equipment, providing access to:

- Maintenance schedule

- Equipment location

- Technical parameters

- Maintenance instructions

- Information about availability of spare parts in warehouse

This enables the maintenance personnel to obtain all necessary information immediately and arrive on-site with the corresponding tools and spare parts.

Benefits of 7D Model

Implementation of a facility management model provides multiple benefits:

- Prevention of emergency repairs

- Quick online access to documentation

- Reduction of management mistakes

- Reduced disposal and recycling costs

- Decreased carbon footprint

For industrial facilities, the system allows monitoring of critical equipment parameters, such as electric motor vibration, and warning about the necessity of replacement or repair.

6D and 7D modelling technologies represent powerful tools for creating energy-efficient buildings and optimising their operation. Small decisions at the design stage can significantly influence the costs throughout the entire lifecycle of the building.

The digital twin created within the 7D model contains all information on the building necessary for efficient operation. The model continues evolving with the building and represents an important element of future digital cities, where all buildings can be united into a single intelligent management system.

Implementation of these technologies requires thorough planning and a professional approach, but investments in BIM 6D and 7D modelling are repaid many times at the expense of reduced operational costs and increased real estate management efficiency