Project Deliverables: Additive Treatment Plant Reconstruction

Detailed Design Phase Completion Report

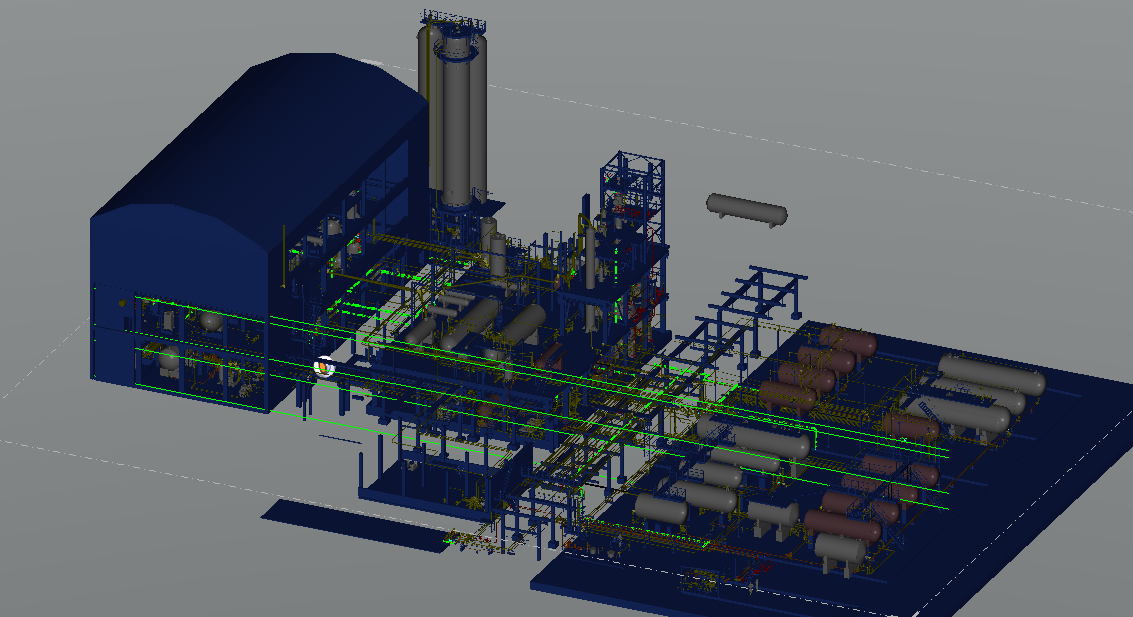

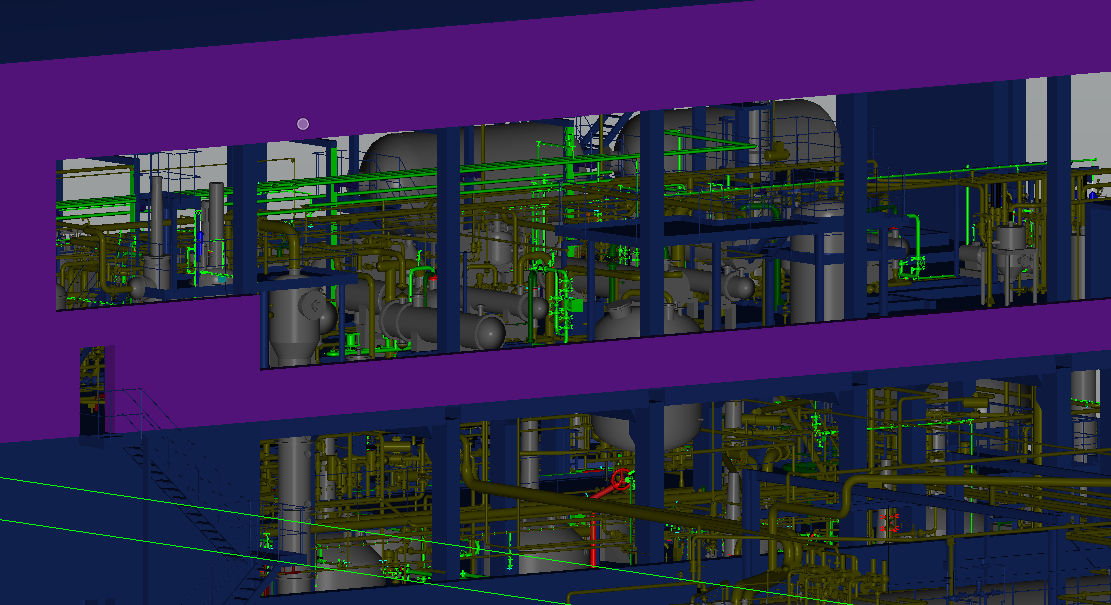

Our engineering team has completed the detailed design phase for the reconstruction of an additive treatment plant, a sludge stripping unit, and a raw material storage facility. This all-encompassing project involved multiple engineering departments working together to deliver a complete technical solution.

Our engineering team has completed the detailed design phase for the reconstruction of an additive treatment plant, a sludge stripping unit, and a raw material storage facility. This all-encompassing project involved multiple engineering departments working together to deliver a complete technical solution.

Production Process Design

The basis of any industrial project lies in its process design. Our team developed a complete set of production process design documents that define how the facility will operate. This work included creating circumstantial equipment data sheets for all major components, developing optimal equipment layouts to ensure efficient operations, and performing critical safety valve calculations to protect the personnel and equipment.

Cross-Disciplinary Coordination

Complex industrial projects require smooth coordination between multiple design disciplines. We prepared and distributed technical assignments to specialists across eight different areas: Electrical Lighting, Automation and Control, Steel Structures, Reinforced Concrete Structures, Architectural Solutions, Heating and Ventilation, Master Plan, and Water Supply and Sanitation. This coordination ensures all aspects of the project work together harmoniously.

Process Lines and Piping Systems

The piping design represents one of the most complex aspects of this project. Our engineers developed an exhaustive piping documentation package that includes isometric drawings and a complete 3D model for 1,000 individual process lines. Each pipeline was carefully analyzed for structural loads and stress to ensure long-term reliability. Additionally, we performed thorough hydraulic calculations to optimise flow rates and pressure drops throughout the system.

Technical Achievement: The 3D piping model encompasses 1,000 individual lines, representing thousands of hours of precise engineering work and ensuring precise installation guidance for construction teams.

Thermal Insulation Systems

Proper thermal insulation is essential for energy efficiency and personnel safety. We delivered a complete thermal insulation package that includes rigorous activity schedules, equipment installation lists, and extensive material lists. Our engineers calculated the optimal insulation thickness for all equipment and pipelines to minimise heat loss while remaining cost-effective. We also prepared lists for electrical heating systems where additional temperature control is required.

Anti-Corrosion Protection

Protecting industrial equipment from corrosion extends the facility lifespan and reduces maintenance costs. Our team developed in-depth anti-corrosion protection guidelines tailored to the specific operating environment. We created intricate schedules of protection activities organised by facility type and prepared complete lists for all protective equipment and materials needed.

This detailed design phase represents months of collaborative engineering work, resulting in a complete technical foundation ready for construction. Each deliverable has been thoroughly reviewed and coordinated to ensure the successful reconstruction of this critical industrial facility.