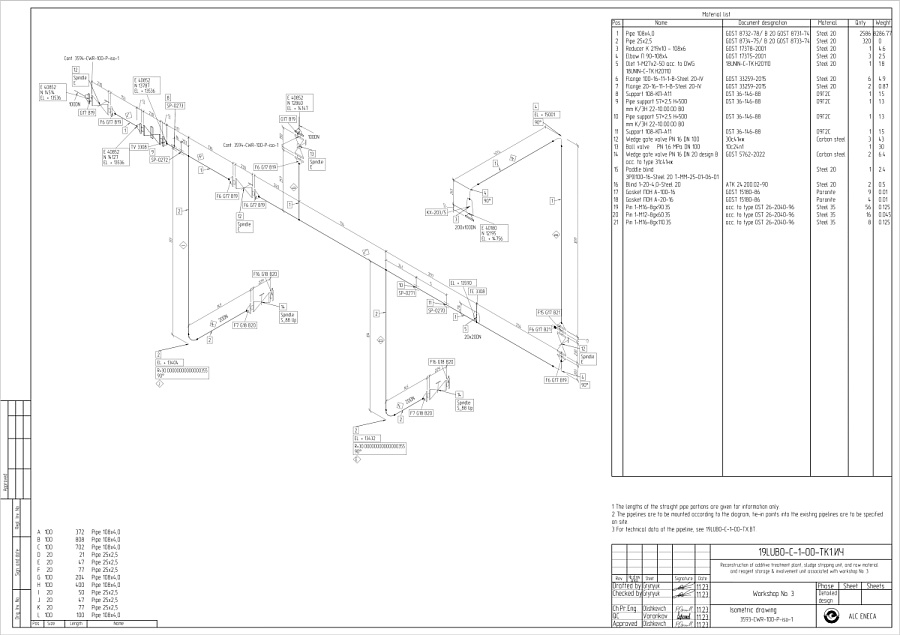

Сhemical plants design

When it comes to the design of chemical plants, often the focus falls on the primary components: pipes, pumps, columns, and heat exchangers operating around the clock. While theoretical knowledge is essential, successful designs hinge on practical insights and a deep understanding of the "hardware."

It seems the most important thing is the chemical reaction. In reality, the most important part is everything that happens before and after it. Raw materials need to be prepared, then something needs to be separated, something purified, something returned to the cycle. And often, it's precisely these "auxiliary" stages that consume up to 99% of all costs. A broken pump or a malfunctioning heat exchanger can paralyze an entire workshop. Problems always come from where you least expect them.

All processes here are divided by a simple principle – what drives them. Based on this "driving force," they are grouped into five categories:

Fluid Mechanics – the movement of liquids and gases. For something to flow, you need a pressure difference between the start and the end of the pipe. The greater the difference, the faster the flow. This also includes processes like the settling of particles from a liquid or the entrainment of solid particles by a gas stream.

Heat Transfer – heating, cooling, condensation, evaporation. The driving force is the temperature difference.

Mass Transfer – the transition of a substance from one phase to another. It works as long as there is a difference between the actual concentration and what it would be at equilibrium. Once they equalize, the process stops.

Mechanical Processes – crushing, grinding, sieving. A certain mechanical force must be applied—the material will then be crushed. If you don't apply enough force, it won't break apart.

Chemical Processes – here, the driving force comes from the realm of chemical thermodynamics.

ENECA Group designs chemical plants that meet the highest standards.