Key Technological Schemes for Hydrogen Production

Let’s explore two primary methods for hydrogen production: from natural gas and through electrolysis of water.

Hydrogen Production in Industrial Facilities

Hydrogen is a critical raw material for many industries.

Its consistent availability in the required volumes and purity is essential for uninterrupted production.

Transporting hydrogen in cylinders or tank trucks from remote facilities is not economically viable and poses logistical risks.

Therefore, large enterprises that consume hydrogen are increasingly building their own generation facilities on-site.

Main Technological Schemes for Hydrogen Production

There are two dominant industrial methods of hydrogen production, with the choice depending on economics, raw material availability, and environmental requirements.

1. Steam Methane Reforming (SMR)

This is the most common method, accounting for the majority of hydrogen production worldwide.

Hydrogen is produced from hydrocarbon raw materials, primarily natural gas (methane, CH₄), by reacting it with steam.

Preparation: Natural gas is cleaned of sulfur compounds that can poison the catalysts.

Conversion: The mixture of purified gas and superheated steam is fed into a reformer reactor.

At temperatures of 800–950 °C and in the presence of a nickel catalyst, an endothermic reaction occurs:

CH₄ + H₂O → CO + 3H₂.

Carbon Monoxide Conversion: The resulting gas mixture (synthesis gas), containing CO and H₂, is directed to a CO conversion reactor.

There, with the addition of extra steam and a different catalyst, CO is converted to CO₂:

CO + H₂O → CO₂ + H₂

This step increases the hydrogen yield.

Purification: Pure hydrogen is separated from the mixture, which now primarily contains H₂ and CO₂.

The most common method is pressure swing adsorption (PSA).

The gas mixture is passed under pressure through adsorbers filled with zeolite or activated carbon, which trap impurities (CO₂, CO, CH₄).

The output is hydrogen with a purity of 99.9–99.999%.

General Considerations:

- Significant heat input is required for the reactor and steam.

- A complex heat recovery system (heat exchangers, flue gas utilization) enhances efficiency.

- A pre-cleaning unit for natural gas is mandatory.

- CO₂ is produced as a byproduct; modern projects incorporate carbon capture and storage (CCS) systems to reduce the carbon footprint.

- The plant requires a substantial supply of natural gas, water, and electricity.

2. Water Electrolysis

This process involves the decomposition of water into hydrogen and oxygen using direct electric current.

Preparation: Water is deeply purified (demineralized) to reduce conductivity and protect the electrodes.

Electrolysis: An electrolytic cell, filled with water or alkaline solution (KOH), is supplied with direct current.

Hydrogen is produced at the cathode, and oxygen at the anode:

2H₂O → 2H₂ + O₂

Separation and Drying: The gases are released from their respective chambers, cooled, and hydrogen undergoes additional drying.

General Considerations:

- Electricity pricing is a crucial factor.

- Capital costs depend on the type of electrolyzer (alkaline, PEM, solid oxide).

- The most advanced PEM electrolyzers require platinum-coated electrodes and expensive polymer membranes.

- Operation is simpler than SMR: no high-temperature furnaces or steam boilers, lower pressure, and higher automation levels.

- The output is high-purity hydrogen, and the byproduct – technical oxygen – can also be utilized.

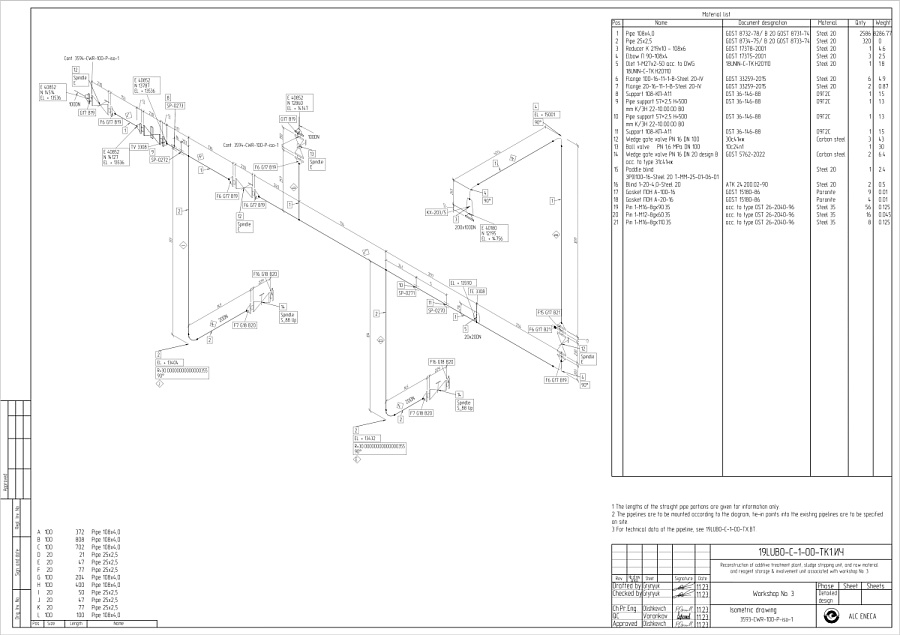

Typical Structure of Hydrogen Production Facilities

Modern facilities often consist of pre-assembled and tested technological blocks:

- Feedstock Preparation Unit: Cleaning of natural gas (for SMR) or water demineralization (for electrolysis).

- Reactor Unit: Reformer with a furnace (for SMR) or a battery of electrolyzers (for electrolysis).

- Product Purification Unit: Primarily a PSA unit for hydrogen separation from impurities.

- Compressor Unit: Multi-stage compressors for supplying hydrogen to the plant network at the required pressure.

- Control and Automation System: Centralized monitoring of parameters and process control from a single dispatch point.

The Role of Hydrogen in Technological Processes

At the plant, hydrogen serves several key roles:

- Actively used for attaching to organic molecules.

- Used in metallurgical processes for direct reduction of iron ore.

- A crucial element for synthesizing many chemical compounds.

- High-purity hydrogen is used to create inert atmospheres.

Safety Considerations

Hydrogen is a flammable gas with a wide range of flammability in air (4 – 75%), low density, and an invisible flame.

Safety systems are designed to prevent the formation of explosive concentrations.

- Forced Ventilation: Essential in enclosed spaces.

- Gas Analysis System: Hydrogen sensors are placed in potential leak points.

- Inert Gas Purging: All lines and vessels are purged with nitrogen before maintenance.

- Flare System: Emergency releases are directed to a high-efficiency flare.