Process Piping. From Frozen Heating Oil to Volatile Petrol: Rules for Designing Railway Terminals

Imagine a giant industrial hub where the heart of fuel logistics beats every day. Dozens of tank wagons, a labyrinth of pipelines, and powerful pumps – everything here is devoted to one goal: to transfer thousands of tons of fuel quickly, safely, and without losses. Creating such a complex organism begins not with metal and concrete, but with design – the painstaking work of engineers who think through each detail, from selecting a pump to explosion protection systems. Let's look under the hood of this project and understand how this well-tuned system works.

Understanding of Product Characteristics for Piping design

It all begins not with iron and pipes, but with understanding what we'll be pumping. Petroleum products aren't just machine oil. Each product has its own temperament and character:

Petrol and Diesel (Light Petroleum Products): Light, volatile, flammable. The main threat is fumes that can be ignited from the slightest spark. They're fluid, causing fewer trouble during pumping in winter.

Heating Oil (Dark Petroleum Products): This is the heavyweight. At low temperatures, it thickens to a paraffin-like state. It cannot be simply drained off – first it must be heated and made fluid.

Misjudging product properties is like filling a car with the wrong fuel, but on a plant scale. The consequences range from equipment failure to explosion. Therefore, the entire subsequent design is tailored to the specific medium.

Special attention is paid to products that when being stored may form volatile compounds or accumulate hazardous impurities. The technological process must include control measures and equipment cleaning regulations to prevent such situations.

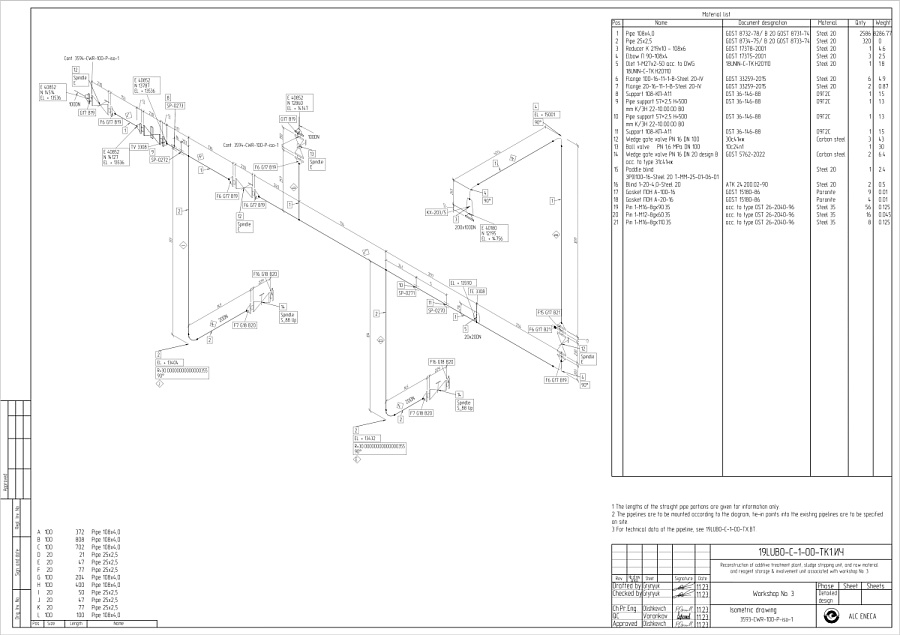

Technological Process in piping design: From Rails to Tank

Everything starts when a tank wagon arrives. Rigid standpipes or flexible hoses are connected to its discharge device. If it's heating oil, the most interesting stage begins. Until the product warms up, it cannot be drained off. To do this there are several methods. The classic method is the tank wagon's steam jacket, where hot steam circulates in wall cavities, gradually melting the substance. Hot heating oil injection is a more modern and efficient approach. Heating oil heated in a heat exchanger (where the heating medium is, for example, mineral oil) is fed into the upper part of the tank wagon. The hot layer gradually warms up the cold product, making it liquid. In contrast to direct steam, this method prevents moisture from entering the fuel. Electric trace heating is also used with immersion electric heaters, flexible heating cables, and infrared heaters.

For diesel and petrol, the process is simpler – these products maintain fluidity at normal temperatures. Nevertheless, even diesel may require heating in winter, for which steam heat exchangers or electric heating are used. When working with light petroleum products, the main task is to minimise evaporation and prevent the formation of explosive vapour concentrations.

Once the product reaches the required fluidity, the gate valves open. Heating oil or diesel enters the inlet header: heating oil gets there by gravity, and diesel can be pumped out by vacuum systems. From here, the fuel starts travelling through the pipelines. The product is drawn in by powerful pumps (centrifugal ones for petrol and diesel, gear pumps for heating oil) and goes under pressure through underground pipes to the tank farm.

At the same time, the safety system is on: when filling the tank, petrol and diesel vapours are not released into the air but return through the recirculation line back to the tank wagon or to the vapour recovery unit.

But technology doesn't end with the main pipeline. Supporting infrastructure also works: if a leak occurs during disconnection or spillage during unloading, the product is collected through drainage channels into an emergency drainage tank. This prevents fuel spills across the territory and protects the environment. Thus, from the moment of connecting the tank wagon to the petroleum product entering the tank, it moves through a closed, safe, and controlled chain.

The Terminal's Brain: Process Control System

To manage this complex mechanism requires a command centre. Here it is an automated process control system (APCS). This is a complex of sensors, controllers, and computers that monitor hundreds of parameters in real time: pressure in pipelines, levels in tanks, product temperature, and vapour concentration.

What does automated process control system (APCS) do?

- Remotely controls pumps and valves from the control room.

- Sets loading modes: precisely here flexible logic for working with multiple loading racks is realised.

- Keeps records of all operations – how much of which product was received, shipped, and remains in tanks.

- Monitors levels: the system receives data from level sensors in tank wagons and tanks to know exactly how much product has been transferred and when to stop the process.

- Prevents overflows: upper level sensors placed in the tanks serve as guarantee – when a critical level is reached, they automatically give a command to stop the pumps.

- Ensures product separation: to prevent mixing of incompatible products, the design provides separate loading/unloading devices or racks.

Loading distribution: Parallel Operation on Multiple Railway Lines

One of the key tasks of the APCS is to organise simultaneous loading or unloading of different products on several railway lines. This is like conducting an orchestra, where each musician is a separate unloading position.

Main workflows:

Parallel loading: The most efficient method. When the tank wagons with the same product (for example, diesel) stand on adjacent railway lines, the system uses the same pump and pipeline, supplying the product in parallel to both racks. This significantly speeds up the process.

Sequential loading: If products are different (for example, petrol AI-92 and AI-95), the system works with them strictly in sequence. First it completely maintenances one tank wagon, flushes the loop or uses a separate pipeline, and only then begins loading another product to avoid mixing.

Individual loading: For special products (for example, aviation kerosene) or during repairs, a dedicated, independent pipeline is used that is not connected to common headers.

Note. Regardless of the scheme, the emergency shutdown system operates for all railway lines simultaneously. An accident on one rack will cause stopping loading on all the lines connected.

Safety Complex in Process piping for fuel transportation

At a facility like this, safety is not just a point given in the instructions, but a complex of engineering systems working as a single organism.

Explosion and Fire Prevention:

-Flame arresters: These are guards on vent valves of the tanks. They prevent external flames from getting inside by extinguishing them in a metal filter.

-Inert gas system (Nitrogen): Chemical protection against explosion. Inert gas is pumped into the tanks with petrol and diesel, displacing oxygen. No oxygen – no explosion

-Gas analysers and threshold limit value control: These devices sniff the air 24/7, tracking the concentration of dangerous vapours. When the threshold limit value (maximum permissible concentration) is exceeded, they sound an alarm so operators can take measures before a hazardous situation arises.

-Equipment monitoring after repairs: Special attention is paid to prepare the tanks for filling after repairs – strict inspection regulations are developed to eliminate the possibility of explosion

Emergency Shutdown and Equipment Protection:

-ESD system (emergency shutdown protection): This is the terminal's nervous system. When any sensor triggers (gas analyser, pressure or temperature sensor), ESD automatically stops the pumps and closes quick-opening gate valves, isolating pipeline sections in seconds.

-Remote pump shutdown: All pumps are equipped with emergency shutdown systems with control posts located in safe and easily accessible places.

-Protection against fluid hammer: When the load suddenly stops, a control valve automatically opens to protect the pipeline and equipment by redirecting the pump flow.

-Safety valves on the tanks: Protection against physical destruction. If pressure inside the tank becomes dangerously high in case of heating or overflow, the valves automatically open and vent excess vapours in a safe direction.

-Emergency release: The tanks are equipped with jettison systems with remote control for emergency situations. All supply pipelines coming to racks have quick action shutoff devices.

Protection of the systems and utilities:

-Preventing hazardous phenomena: For low-boiling products, special attention is paid to measures against vapour formation, cavitation, and fluid hammer capable of destroying equipment

-Cleaning and blowing-down of the system: All pipelines and headers are connected to inert gas and steam supply systems for safe cleaning and prevention of explosive mixture formation.

-Material resistance: All elements of loading/unloading systems are made from materials resistant to specific petroleum products.

-Electrostatic discharge protection: During all operations, devices for taking-off static electricity discharge shall be used.

Leak Containment:

Drainage system and emergency tanks: Any accidental spill won't go into the ground. The whole territory is equipped with slopes and channels that direct the spilled fuel to special drainage tanks for subsequent disposal.

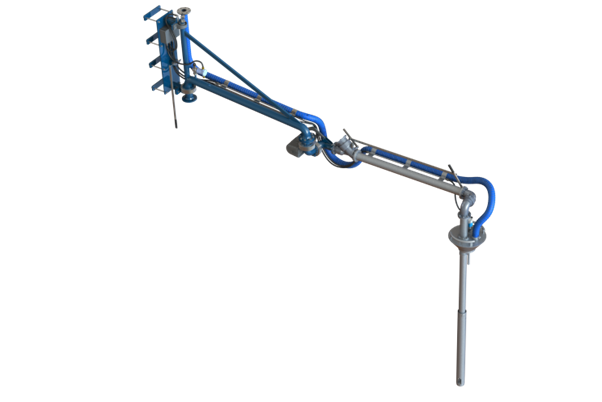

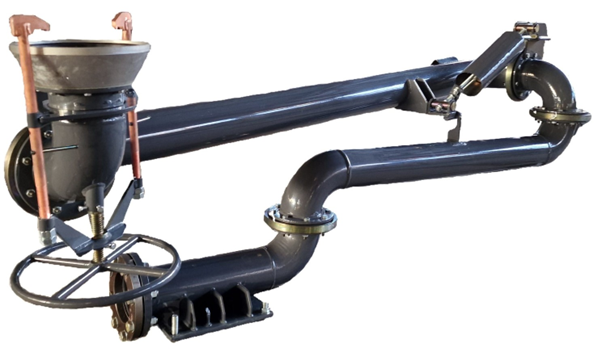

The Terminal's Hands and Feet – Loading and Unloading Devices

These are contact points between a tank wagon and a pipeline.

Main types of fuel Loading and Unloading Devices:

- Standpipes (top loading): Classic for light products. The hose goes from the top into the tank wagon opening. Meanwhile, the above mentioned hazardous vapours are quick, but actively released.

- Bottom/top loading/unloading systems: Modern and safe. A special coupling is connected to a nozzle at the bottom/top of the tank wagon. This minimizes splashing and evaporation.

Key requirement – all operations with light petroleum products shall be conducted in a closed manner under pressure, which minimises evaporation and fire risk.

Transport Vessels – Tank Wagons in process design

Railway tank wagons aren't just barrels on wheels.

They're specific for each type of the fuel.

For light products (petrol, diesel): Unheated tank wagons. Their main task is to prevent vapour escape.

For heating oil: They are a sort of a vacuum insulated water bottle with heating. They have thermal insulation and steam jackets – cavities along the sides where the steam is supplied to melt the thickened product or use a heated product supply system inside the tank wagon.

Tank wagon safety.

When installing the tank wagons for loading, wheel blocks shall be used, and connections shall be checked to prevent leaks.

Safety zones: In the radius of possible gas contamination, all potential ignition sources, both permanent and accidental ones, shall be excluded.

Prohibitions: The intermediate tanks may not be placed under the railway lines, except for the cases with high-temperature petroleum products (flash point >120°C)

Rack infrastructure:

Evacuation routes: The stairs made from non-combustible materials shall be located at the ends and along the length of the racks every 100 meters. The stairs shall be at least 0.7 m wide with 1:1 slope

Handrails: All stairs and service platforms of the racks shall be equipped with protective handrails at least 1 meter high.

Here, safety is not just a word; it represents a well-thought-out system of protective measures. Modern technologies not only allow for efficient management of fuel flows but also enable immediate responses to any deviations. Automated systems monitor every step, while multiple layers of redundant safety systems ensure reliability even in the most challenging situations.

The attention is paid to all technological processes that allows us to enjoy the benefits of modern life without considering the complex journey that fuel takes from the tanker to the gas station. Behind the seamless operation of the terminal lies not only metal and technology but also the knowledge, experience, and responsibility of the people who design and maintain these piping systems. ty of the people who design and maintain these piping systems.