The benefits of Revit for electric power supply design

Category

Design

Date

03.12.2024

Author

Eneca

Share

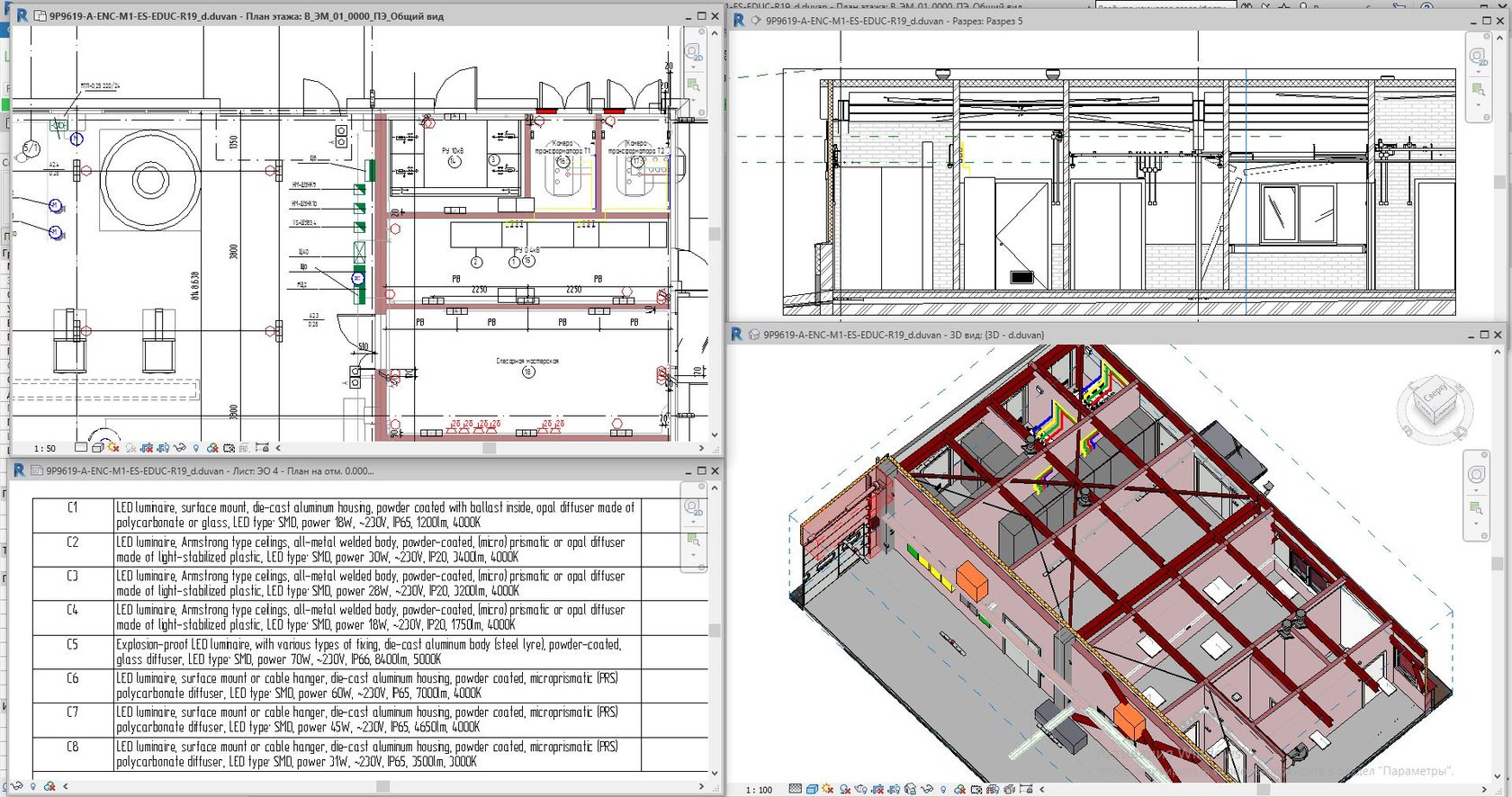

As time passed, software developers expanded Revit's functionality. Also some forward-thinking manufacturers began to develop families of the fabricated equipment to be used in BIM-Modeling and offered special plugins for Revit. This made it possible to further expand the functionality of Revit and automate the process of developing electric power supply design discipline, which led to an increase of quality and information content of the BIM-Model as a whole. Nowadays, there is a continuing trend of involving equipment manufacturers in the process of creating families for BIM-Modeling.

We present a comparative analysis of 2D and 3D approaches applied in electric power supply design:

| Criteria | 2D | 3D |

|---|---|---|

| Transfer of design assignments among specialists of different design disciplines | Available with external links | Available with special work methods. Visibility and information content of the task are improved |

| Opportunity for several engineers to work on the design discipline in the same file at the same time. | There is no way that several engineers can work on the same project file at the same time. It’s possible to organize work in several files using external links. | Revit allows several engineers to develop a model of one design discipline. The changes are visible after each synchronization in real time. Experts work with one model file. Visibility and efficiency of the work are high |

| Automatic check of the project for collisions (monitoring of undesirable intersections, overlapping of objects) | The check cannot be carried out because there are no virtual models of objects and equipment in 2D design | Revit allows you to carry out a check for collisions. Algorithms for 3D object interaction are laid down. It significantly saves time for check and greatly reduces the likelihood of mistakes. |

| Opportunity for automatic diagram building | There is no opportunity, because it is impossible to create objects in a 2D project, the information from which can be used for automatic diagram building | It’s possible to build diagrams based on 3D object information using plugins. When changing the hardware configuration, the diagrams are updated in one click. |

| Opportunity for automatic equipment selection | There is no possibility, because it is impossible project to create objects in a 2D, the information from which can be used for automatic equipment selection | It is possible to select the equipment (cables, circuit breakers) automatically based on 3D object information using plugins. |

| Display of the equipment used in the project in plans, sections, specifications, lists | In 2D design, each plan, section, specification, list is an independent object and created separately. A designer needs to constantly monitor the location and characteristics of the equipment, which is located at different points in the project. There is an increased likelihood of discrepancies, when making changes | When designing in Revit, a single model is created, on the basis of which various plans and sections can be built. When moving (changing, deleting) a 3D object, the graphic and text information in plans, sections, schedules, specifications changes in real time. The properties of a 3D object can be monitored from different points in the project. All this increases the speed and accuracy of project creation as well as significantly reduces the risk of mistakes, when making changes |

| Visualization of the equipment in the project | There is no opportunity to implement an automatic 3D visualization of the object. If necessary, the visualization can be carried out separately and from the scratch. When making changes, it is necessary to correct both the design and the visualization that increases the likelihood of discrepancies | Visualization is possible at any design stage , which increases the information content of the project and reduces design costs. The customer can assess himself, how much his expectations coincide with the design solutions. When making adjustments, the probability of mistakes is low, due to the fact that the model is a digital copy of the future object. Visualization is possible both using built-in functionality and third-party software systems |

| Using the project for operation needs | During the operation, it’s possible to use each design discipline separately. Low degree of clarity. If reconstruction is necessary, it’s most likely, you will have to carry out the project "from the scratch" | During the operation, it’s possible to use both individual drawings and the entire model. You can quickly find the necessary equipment in the large project, find out its location in space and characteristics. Information about the equipment nearby is available. If reconstruction is necessary, there is all the initial data for the quick performance of design work without visiting the site. |

Based on the facts presented, it can be concluded that BIM has a lot of important benefits to be applied in the development of electric power supply design disciplines that will have a positive effect on the cost, quality and timing of the construction of the object. There is also an opportunity to develop and expand the functionality of such an approach, and this is not unimportant in the modern, constantly changing world.

Our Electrical Modeling Services

- BIM Electrical Modeling

- Internal and external lighting design (including the emergency lighting system design)

- MV & LV single line diagrams, specifications of equipment, products and materials

- Power supply and Substations design

- Low Voltage Systems Back-Up Power design

Analysis

- Network study & Load flow analysis

- EMG/UPS sizing calculations

- Transformers sizing calculations

- Indoor/Outdoor illumination levels calculation