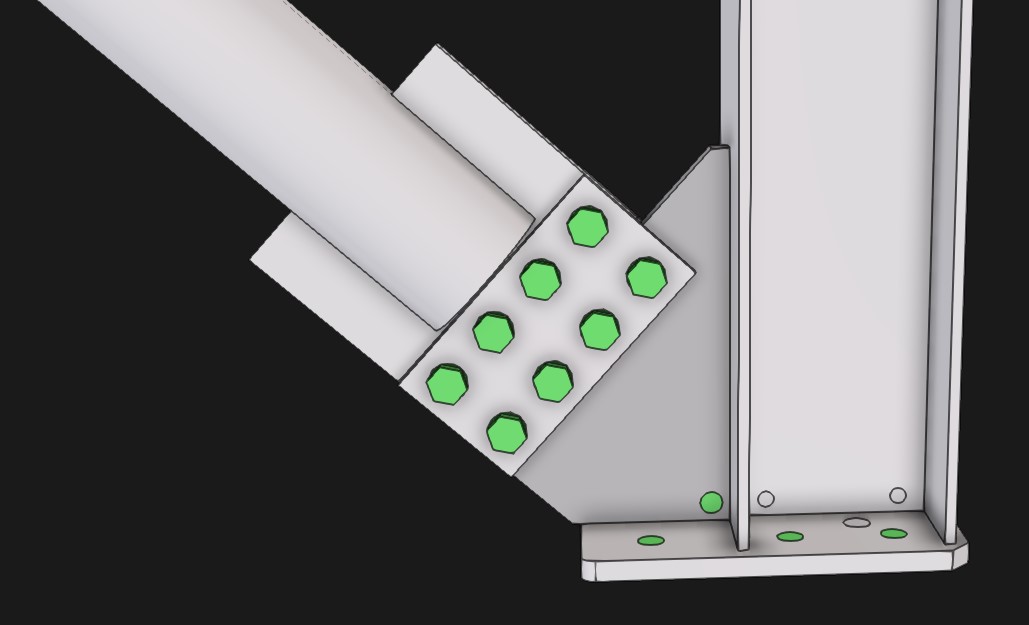

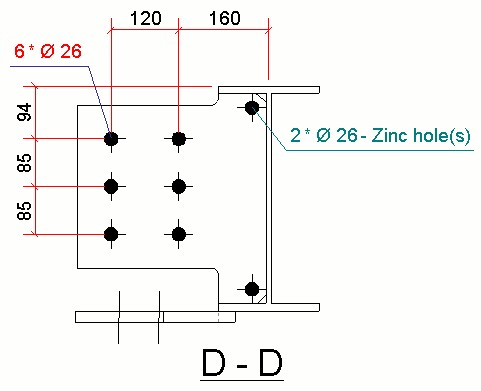

Corrosion Protection Maximisation: The Benefits of Hole Modelling for Hot-Dip Galvanized Steel Structures

Let’s learn how strategic hole modelling before hot-dip galvanizing procedure significantly improves the efficiency and longevity of corrosion protection, reducing maintenance costs and extending the lifespan of your steel structures.

Corrosion protection is an important aspect of metal structure design. One of the most effective protection methods is galvanizing,which requires preliminary modelling of drainage holes in structures.

Why is modelling drainage holes in metal structures necessary for hot-dip galvanizing?

1. Ensuring Uniform Coating

During hot-dip galvanizing, metal is immersed in molten zinc. If drainage holes are not provided, zinc can pool inside the structures, leading to uneven coating. This can create weak spots that will be susceptible to corrosion.

2. Elimination of Air Pockets

Drainage holes help avoid forming air pockets inside the structure. Air pockets can prevent zinc penetration and create coatingless areas, which reduces anti-corrosion properties of the structure.

3. Treatment Process Simplification

Proper design of drainage holes simplifies the hot-dip galvanizing process and makes it more efficient. This makes it possible to reduce processing time and decrease material and labour costs.

4. Structural Strength Enhancement

The absence of stagnant zinc inside the structure contributes to uniform load distribution and reduces the risk of stresses that can lead to failure or deformation of structural elements.

5. Aesthetic Characteristics Improvement

Drainage holes help avoid excessive zinc accumulation, which can negatively affect the appearance of the finished structure. A clean and neat coating looks more attractive and meets modern quality standards.

Designing drainage holes for hot-dip zinc in metal structures is a key aspect that affects the quality of corrosion protection, strength, and longevity of structures. Considering all the above mentioned factors, it can be affirmed that proper design of drainage holes is a necessary condition for reaching high quality standards in the production and operation of metal structures.