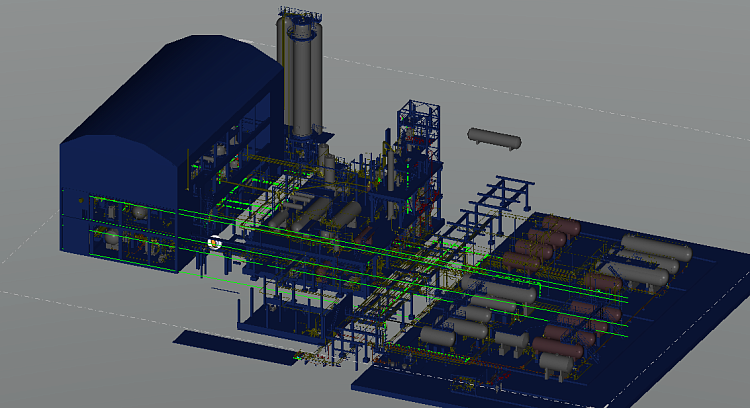

Additive treatment plant reconstruction

Development of the detailed design for additive treatment plant reconstruction including a sludge stripping unit, a raw material and reagent storage, and involvement unit associated with the workshop.

Project scope:

- Set of documents for Production Process Design;

- Equipment data sheets, equipment layouts, calculations of safety valves;

- Assignments transferring for “Inner Electrical Lighting”, “Automation and Control”, “Steel Structures”, “Reinforced Concrete Structures”, “Architectural Solutions”, “Heating, Ventilation, Air Conditioning”, “Master Plan”, “Inner Water Supply and Sanitation"

- Set of documents for Process lines design

- Isometric drawings and 3D model of pipe manifold comprising 1000 lines have been developed. The pipelines have been calculated in terms of loads and stress, and a hydraulic calculation has been conducted.- A set of documents for Thermal Insulation design. This includes a list of thermal insulation activities, a list of equipment to be installed, and materials.

-The thickness of the thermal insulation to be applied to the equipment and pipelines has been calculated, and an assignment for electrical heating has been prepared.

- Documents for anti-corrosion protection of the equipment and pipelines. Anti-corrosion protection guidelines have been developed, along with a list of anti-corrosion activities intended for the facilities to be protected, and lists of equipment, items, and materials.

Based on their experience, I can recommend Eneca.

We appreciate Eneca’s readiness to support us with BIM modeling on short notice, as well as their flexibility in providing the necessary resources to meet a strict deadline. All modeling was completed within two weeks, with a division into lots. Eneca’s specialists were always willing to take the time to discuss our concerns and accommodate additional requests.

Eneca’s strong expertise in Revit and professional experience in structural design enabled their team to quickly grasp Implenia’s high modeling requirements. The BIM model was developed in accordance with the 3D BKP Model guidelines and Implenia’s standards, ensuring compliance with parameter and element naming rules as per Baukostenplan Hochbau. Eneca’s detail-oriented and structured approach contributed to the creation of a high-quality BKP model aimed at automating the calculation of construction volumes and costs.

I am pleased with the quality of services provided by ENECA and can confidently recommend them to others in need of similar BIM modeling services.

The design process always requires flexibility and capability to think differently, and we were pleased to see Eneca’s readiness to support us and solve all the project issues together. When there was a need to do some quick revisions at a very late stage, Eneca's specialists performed them in a high qualitative and timely manner. The technical competence and deep Tekla knowledge of Eneca’s team as well as their high-performance efficiency and always keen in continuous improvement, provided us an important support in our engineering process.

30.07.2021