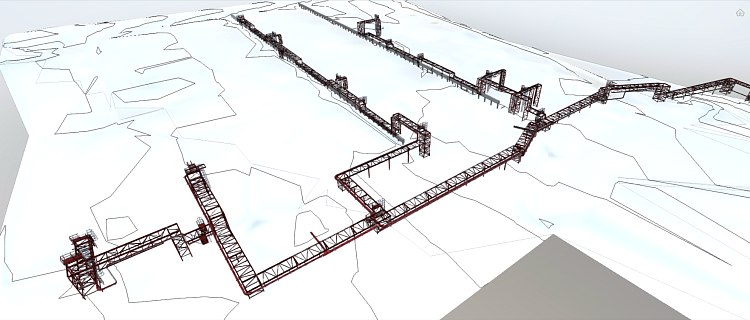

Infrastructure for a northern industrial park

Meeting deadlines in projects is a common challenge, but what if an entire town's well-being depended on it? That's exactly what our team faced when designing a project for replacing the heating, water supply, and sewage networks for a town in the Far East permafrost zone. The existing networks were deteriorating, and there was a short one to two-month window during the summer when the ground wasn't frozen to carry out the construction. Meticulous planning was essential to ensure the project could be completed within this limited timeframe.

Logistics and supply chains posed another hurdle. With the town located in a remote area, helicopters were sometimes the only means of access. This logistical constraint had to be carefully considered during the design phase, and accurate calculations and design were crucial to avoid supply chain disruptions. Delays would not only push the project completion date back by at least a year but also risk the lives of residents living with deteriorating utilities.

We take pride in our team's ability to overcome these challenges and complete the project successfully. Through meticulous planning and coordination, leveraging tools like BIM, we maximized the use of the short summer window and accomplished as much work as possible on-site to deliver the project on time.

Location of the object is a permafrost region. Seismicity of the work area - 6 points. According to their seismic properties, soils belong to 1st category.

The project provides for the reconstruction of existing heat supply networks with a length of 18025m, water supply networks with a length of 15744m, sewerage networks with a length of 12700m, as well as laying new ones with a length of 2800m. The project used pipes of the "Arctic" and "Multiline" type with diameters of 225-500 mm.

In the existing buildings of consumers, the reconstruction of 74 Individual Heating Plants. To connect utility lines to the floating nuclear power plant, a connection unit with the necessary shut-off valves and instrumentation is being built.

The project also provides for the construction of local treatment facilities with a capacity of 104.805 m3 / h

Based on their experience, I can recommend Eneca.

We appreciate Eneca’s readiness to support us with BIM modeling on short notice, as well as their flexibility in providing the necessary resources to meet a strict deadline. All modeling was completed within two weeks, with a division into lots. Eneca’s specialists were always willing to take the time to discuss our concerns and accommodate additional requests.

Eneca’s strong expertise in Revit and professional experience in structural design enabled their team to quickly grasp Implenia’s high modeling requirements. The BIM model was developed in accordance with the 3D BKP Model guidelines and Implenia’s standards, ensuring compliance with parameter and element naming rules as per Baukostenplan Hochbau. Eneca’s detail-oriented and structured approach contributed to the creation of a high-quality BKP model aimed at automating the calculation of construction volumes and costs.

I am pleased with the quality of services provided by ENECA and can confidently recommend them to others in need of similar BIM modeling services.

The design process always requires flexibility and capability to think differently, and we were pleased to see Eneca’s readiness to support us and solve all the project issues together. When there was a need to do some quick revisions at a very late stage, Eneca's specialists performed them in a high qualitative and timely manner. The technical competence and deep Tekla knowledge of Eneca’s team as well as their high-performance efficiency and always keen in continuous improvement, provided us an important support in our engineering process.

30.07.2021