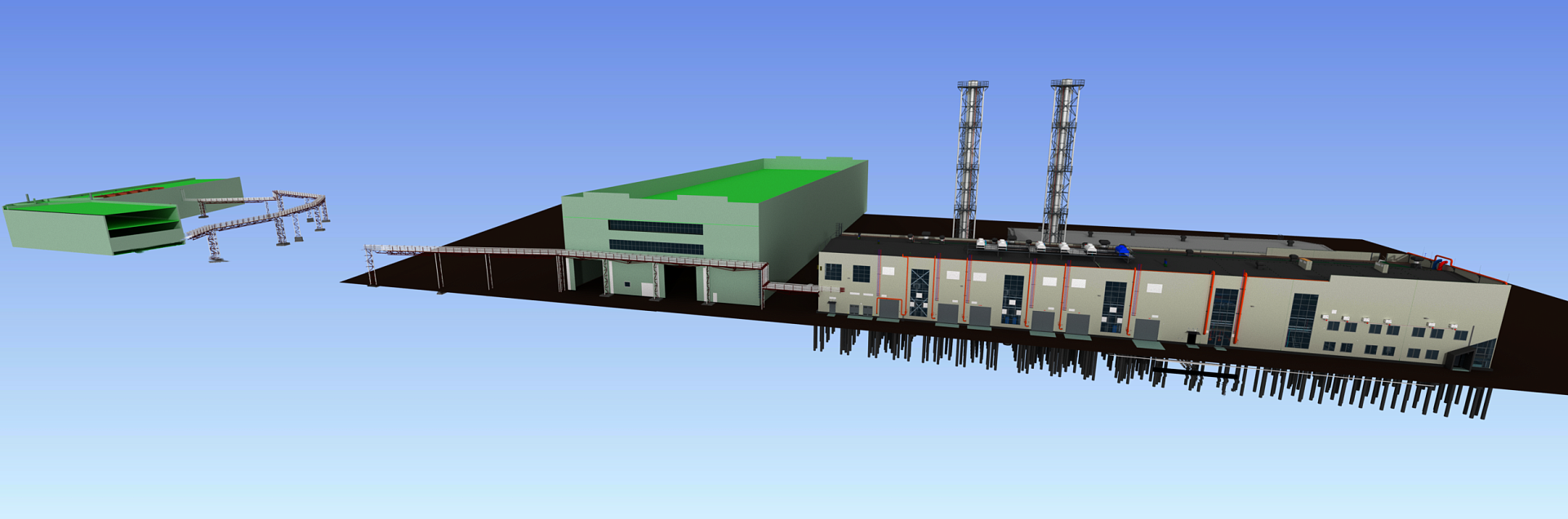

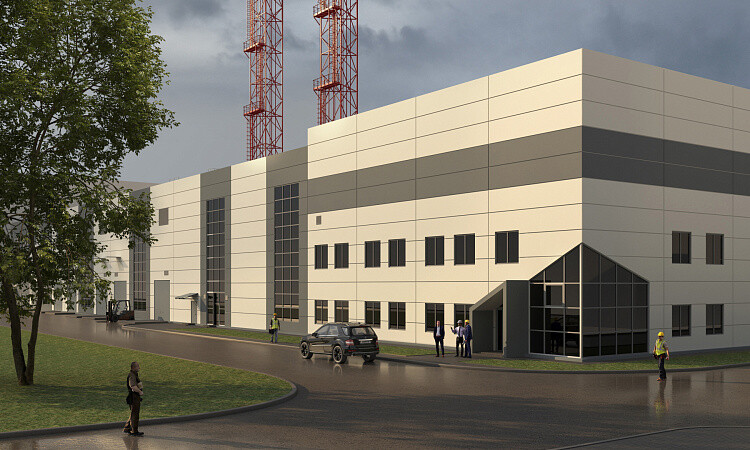

Mini-CHP on wood chips

The CHP is designed for producing heat and electricity for the plywood mill and the nearby village. It is running on biomass obtained from wood processing waste.

The main equipment of the CHP comprises:

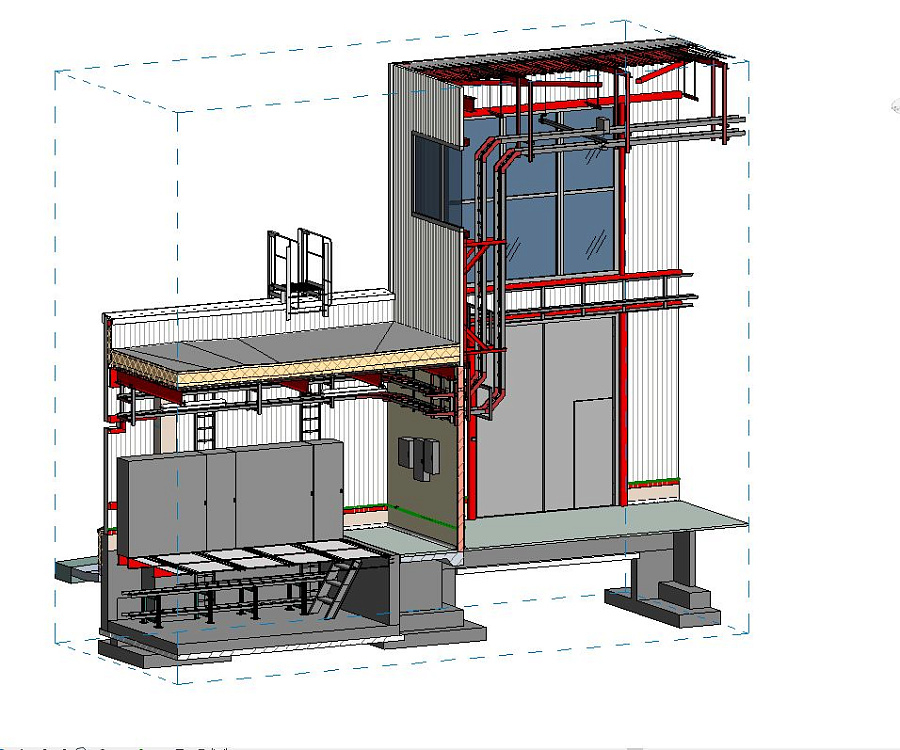

- Four units, including biomass furnaces and steam boilers for superheated steam production (flow=25 t/h, temperature =440 ºC, pressure=39,2 bar each)- One steam turbine of electrical power 7,7 MW.

Considering the project complexity, all the main structures and systems were modeled in Revit with the LOD up to 400. Architectural, structural, MEP and Process Engineering models were put together in one integral model for BIM Coordination. It has ensured smooth workflow, more optimal design solutions and client involvement in the design process at all design stages.

Software: Revit, Autodesk Construction Cloud, Tekla

Based on their experience, I can recommend Eneca.

We appreciate Eneca’s readiness to support us with BIM modeling on short notice, as well as their flexibility in providing the necessary resources to meet a strict deadline. All modeling was completed within two weeks, with a division into lots. Eneca’s specialists were always willing to take the time to discuss our concerns and accommodate additional requests.

Eneca’s strong expertise in Revit and professional experience in structural design enabled their team to quickly grasp Implenia’s high modeling requirements. The BIM model was developed in accordance with the 3D BKP Model guidelines and Implenia’s standards, ensuring compliance with parameter and element naming rules as per Baukostenplan Hochbau. Eneca’s detail-oriented and structured approach contributed to the creation of a high-quality BKP model aimed at automating the calculation of construction volumes and costs.

I am pleased with the quality of services provided by ENECA and can confidently recommend them to others in need of similar BIM modeling services.

The design process always requires flexibility and capability to think differently, and we were pleased to see Eneca’s readiness to support us and solve all the project issues together. When there was a need to do some quick revisions at a very late stage, Eneca's specialists performed them in a high qualitative and timely manner. The technical competence and deep Tekla knowledge of Eneca’s team as well as their high-performance efficiency and always keen in continuous improvement, provided us an important support in our engineering process.

30.07.2021