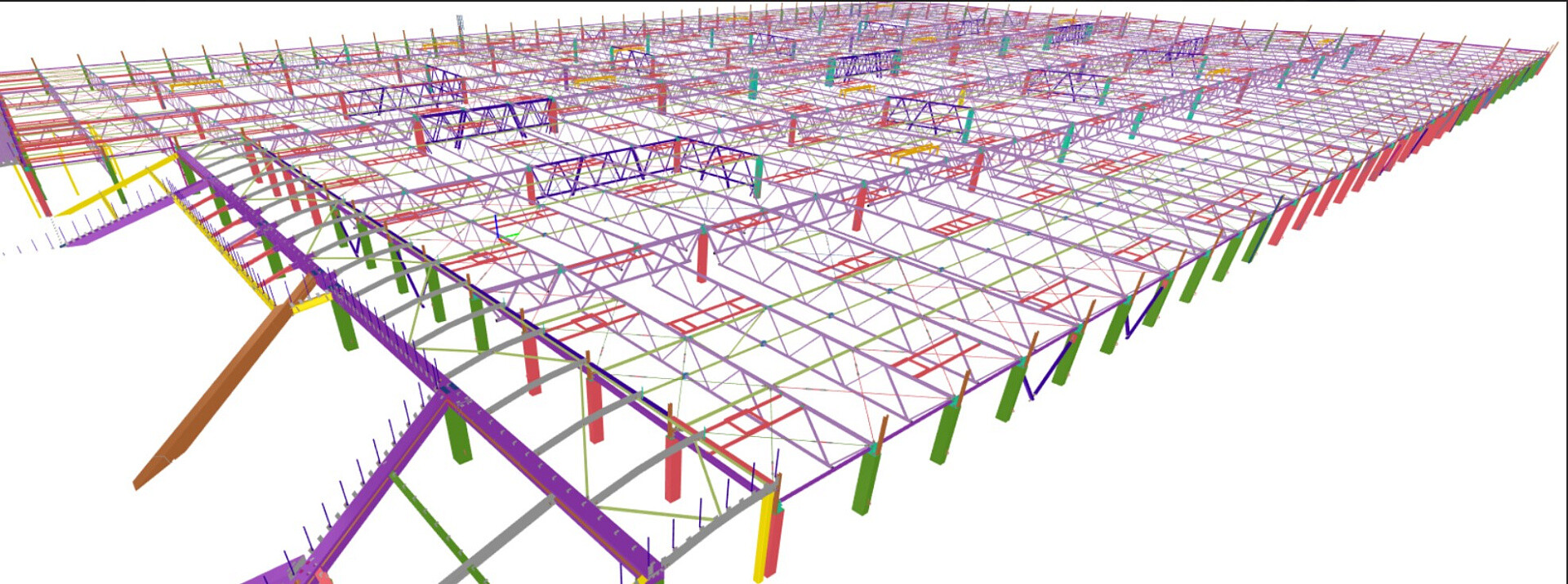

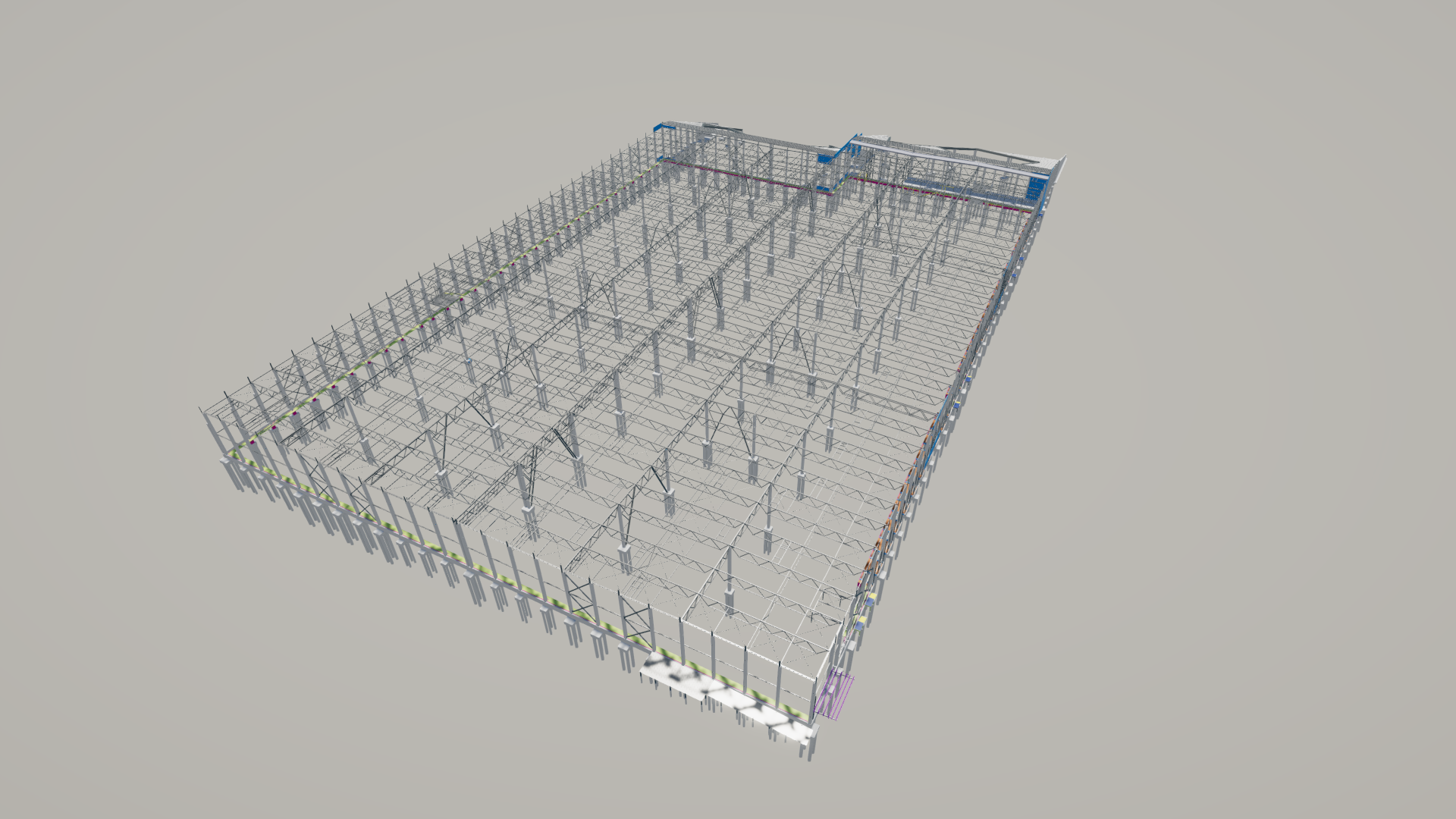

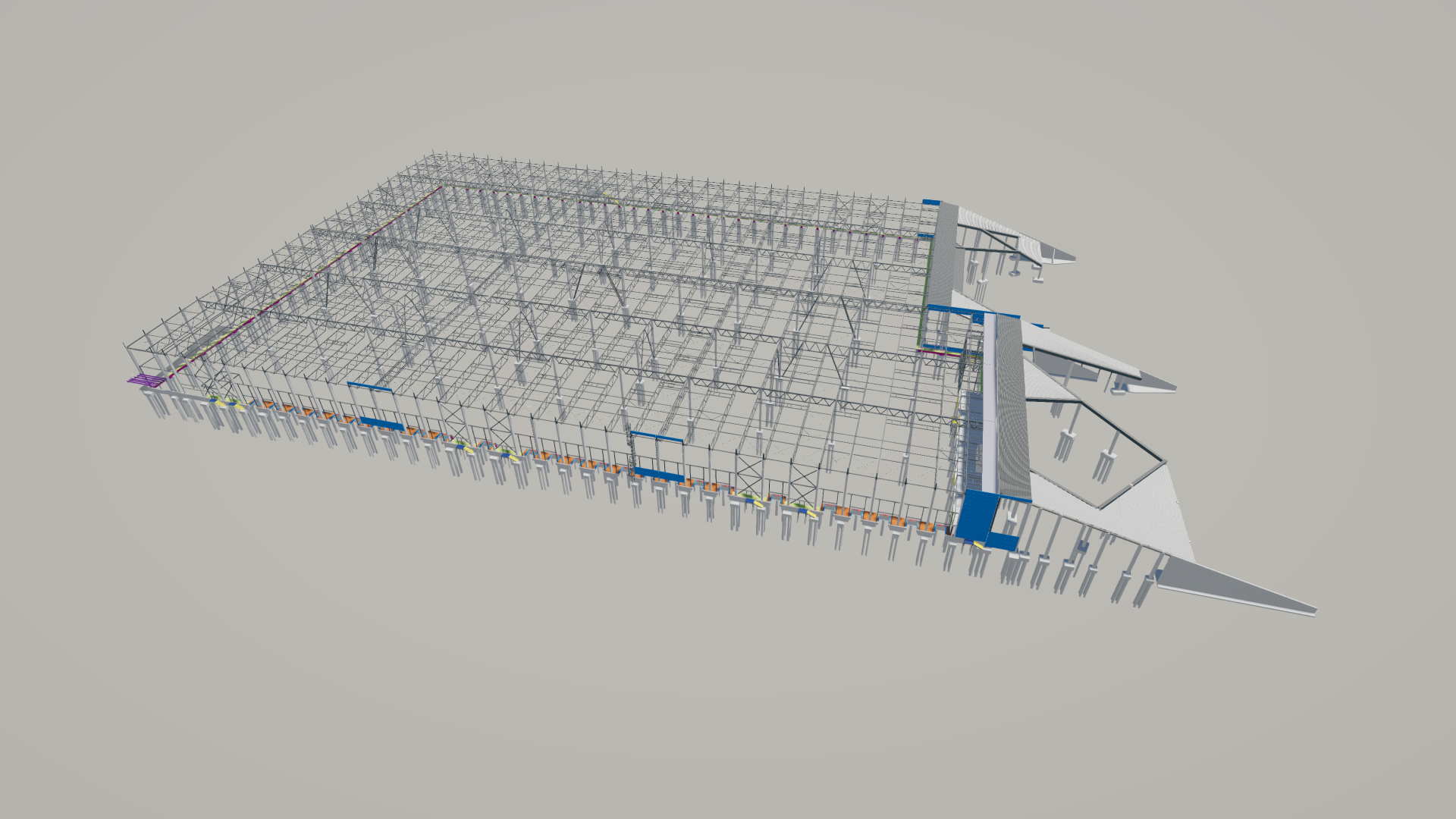

Warehouse with steel trusses

Warehouse with steel trusses design.

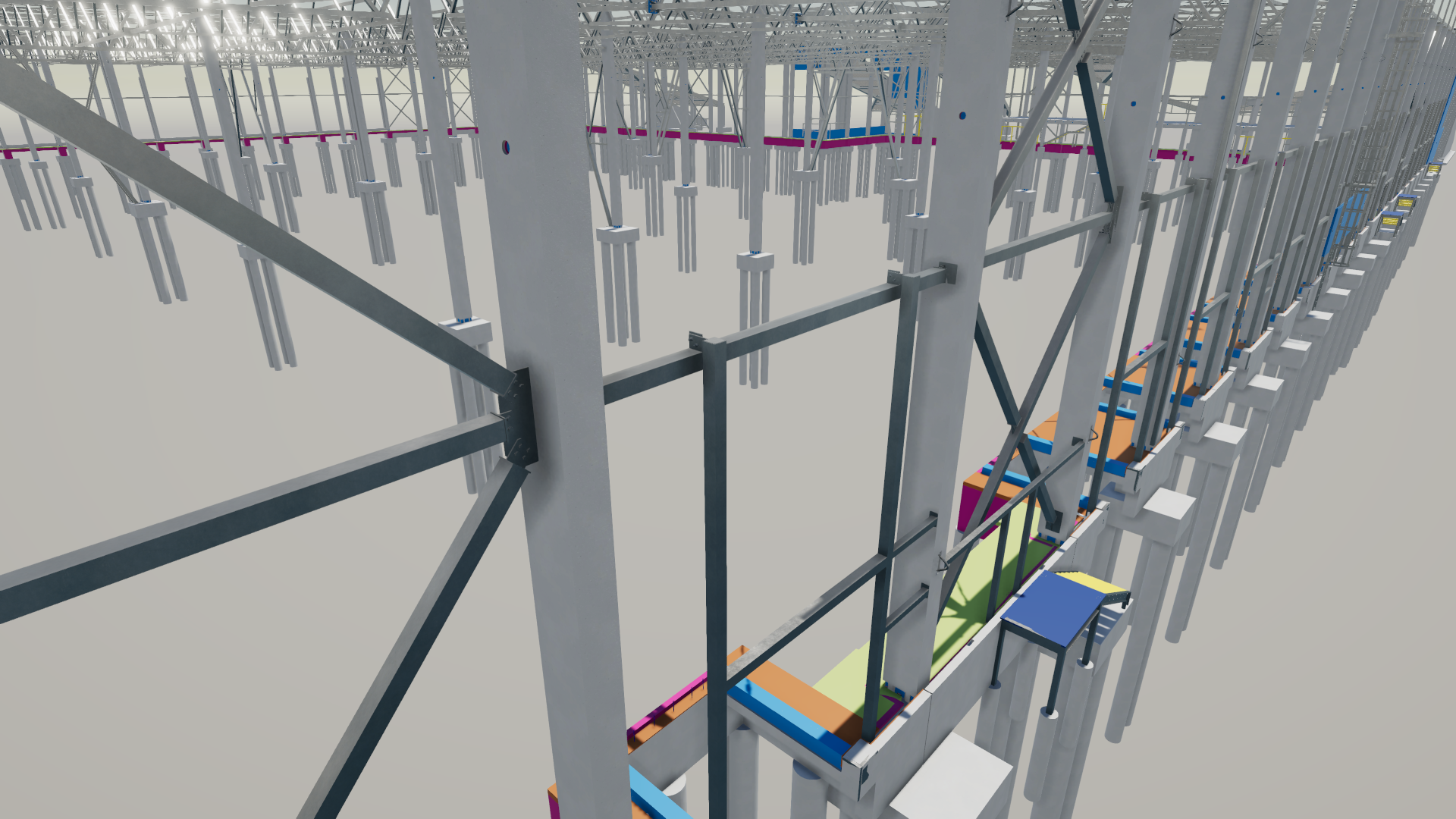

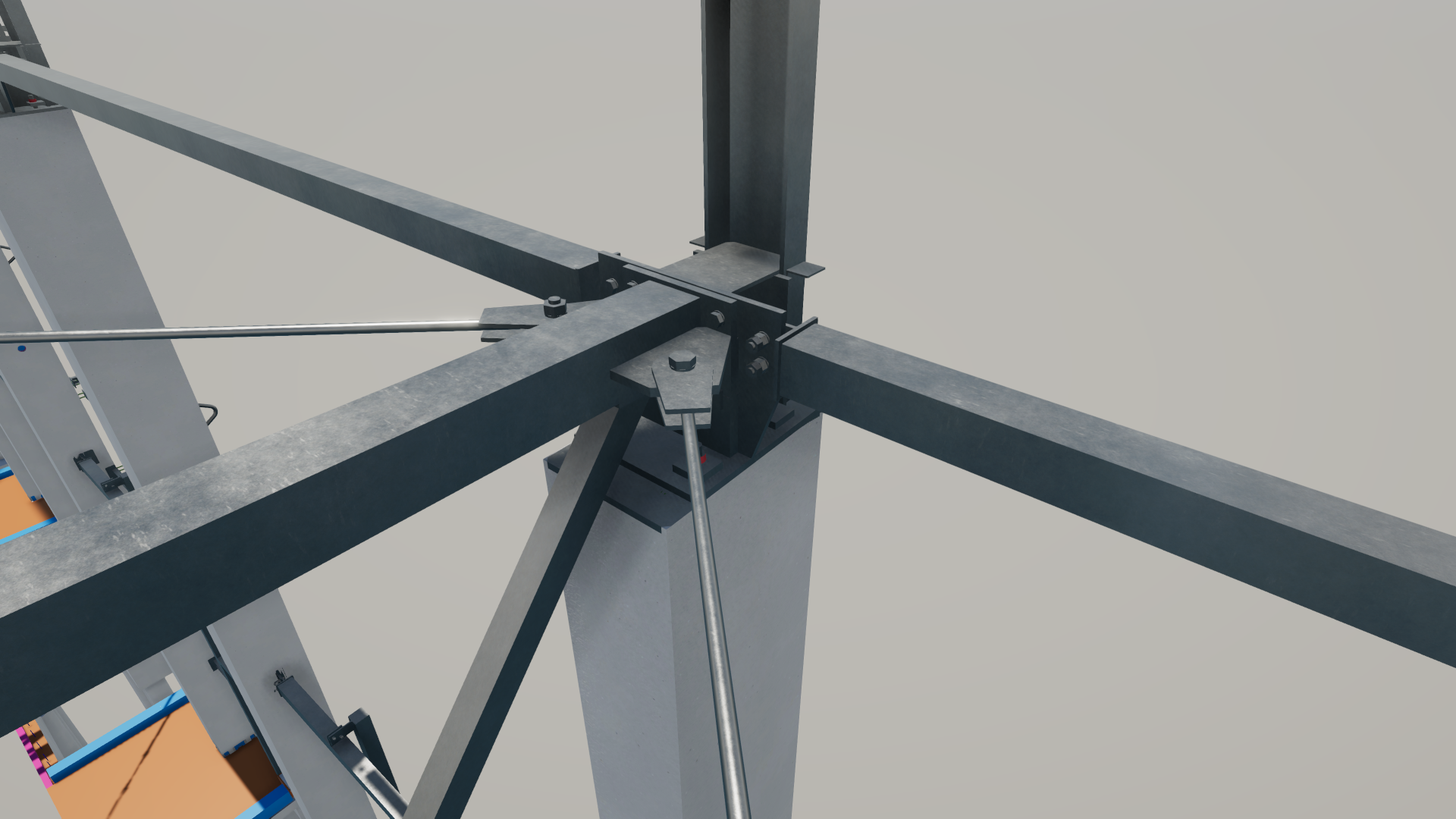

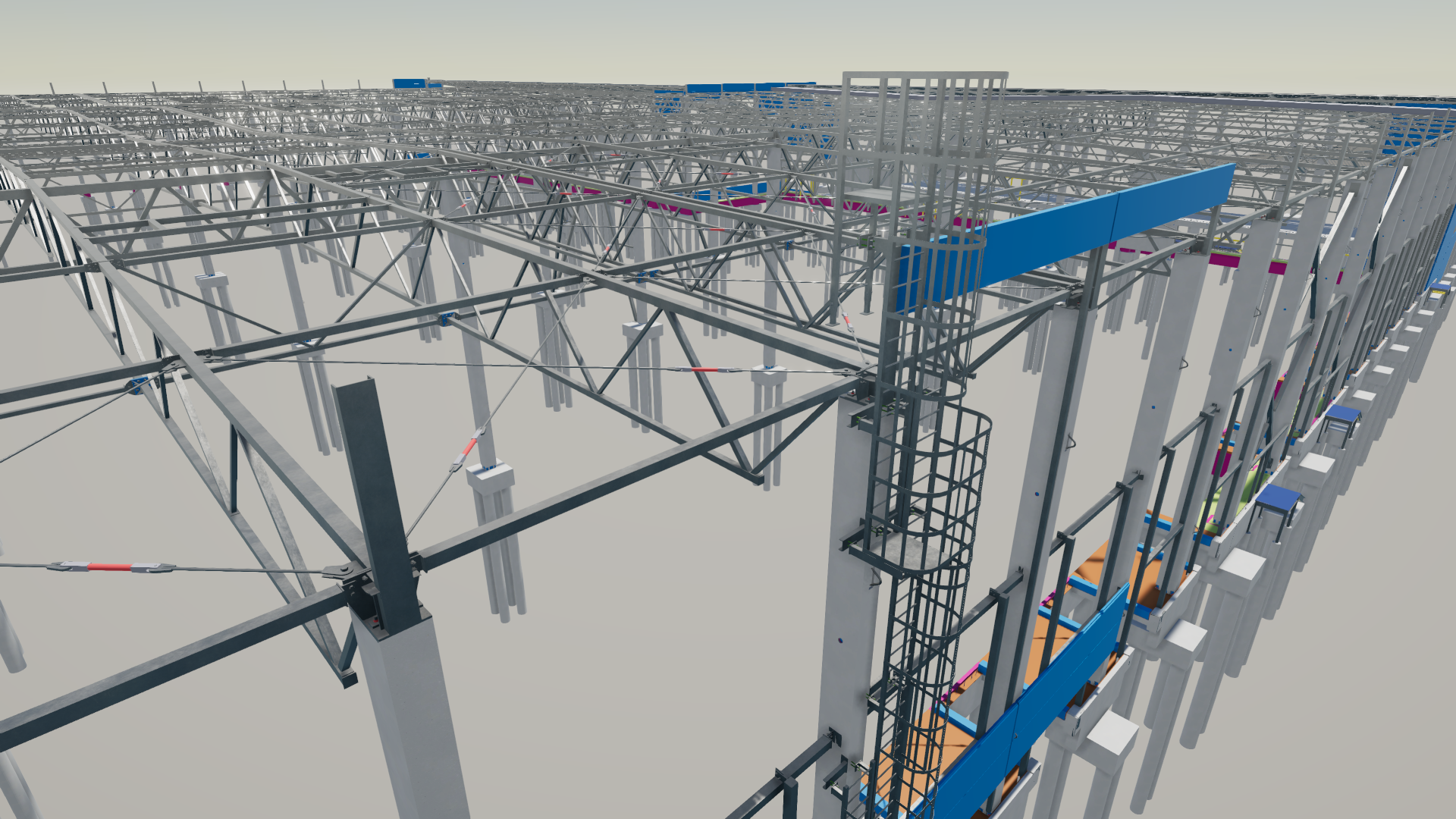

Key features:- steel covering supported by bar joists on long-span trusses

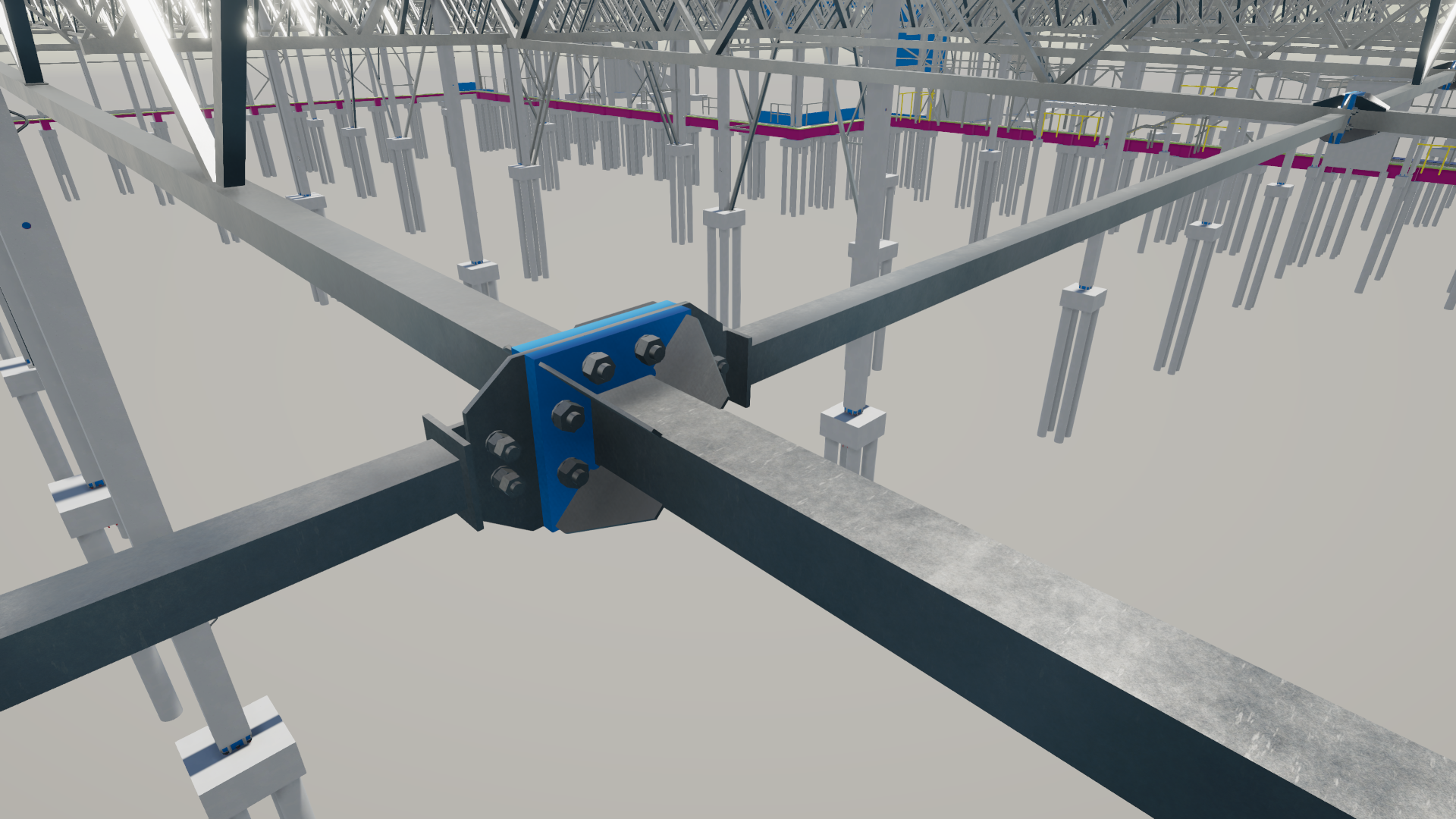

- fairly large scope of calculations for the connections of truss elements

- steel consumption - 1400t (warehouse building roof)

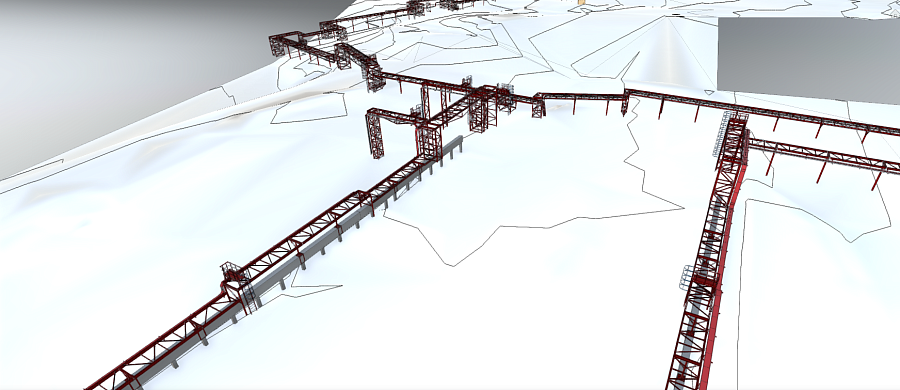

Scope of work:

- Connection calculation in IdeaStatica

- Modeling in Tekla

- GA drawings, workshop drawings

When it comes to constructing warehouses, steel structures have become the go-to solution for many businesses. Their durability, flexibility, and cost-effectiveness make them ideal for various industrial needs. In this article, we'll explore how to design efficient steel structure warehouses that meet your business requirements while optimizing space and functionality.

Steel structure warehouses, also known as steel frame buildings, are constructed using a framework of steel columns and beams. This framework supports the building's roof and walls, allowing for large, open spaces without the need for interior columns. This feature is particularly beneficial for warehouses, where maximum usable space is crucial.

Key Considerations in Designing Steel Structure Warehouses

When designing a steel structure warehouse, several factors need to be considered to ensure efficiency and functionality.

Site Selection and Preparation

Choosing the right location for your warehouse is critical. Consider proximity to transportation networks, suppliers, and customers. Once the site is selected, proper site preparation, including leveling and grading, is essential to ensure a stable foundation for your steel structure.

Layout and Space Optimization

An efficient layout is crucial for maximizing the use of space in your warehouse. Consider the flow of goods, storage requirements, and accessibility when designing the layout. The absence of interior columns in steel frame buildings provides flexibility in arranging storage racks and equipment.

Structural Design and Load Considerations

The structural design of your warehouse must account for various loads, including dead loads (the weight of the building itself), live loads (the weight of stored goods and occupants), and environmental loads (such as wind and snow). Collaborate with structural engineers to ensure the design meets safety standards and local building codes.

Insulation and Ventilation

Proper insulation is essential to maintain a controlled environment inside the warehouse, especially if you're storing temperature-sensitive goods. Additionally, adequate ventilation is necessary to ensure air quality and prevent the buildup of moisture, which can lead to corrosion in steel structures.

Based on their experience, I can recommend Eneca.

We appreciate Eneca’s readiness to support us with BIM modeling on short notice, as well as their flexibility in providing the necessary resources to meet a strict deadline. All modeling was completed within two weeks, with a division into lots. Eneca’s specialists were always willing to take the time to discuss our concerns and accommodate additional requests.

Eneca’s strong expertise in Revit and professional experience in structural design enabled their team to quickly grasp Implenia’s high modeling requirements. The BIM model was developed in accordance with the 3D BKP Model guidelines and Implenia’s standards, ensuring compliance with parameter and element naming rules as per Baukostenplan Hochbau. Eneca’s detail-oriented and structured approach contributed to the creation of a high-quality BKP model aimed at automating the calculation of construction volumes and costs.

I am pleased with the quality of services provided by ENECA and can confidently recommend them to others in need of similar BIM modeling services.

The design process always requires flexibility and capability to think differently, and we were pleased to see Eneca’s readiness to support us and solve all the project issues together. When there was a need to do some quick revisions at a very late stage, Eneca's specialists performed them in a high qualitative and timely manner. The technical competence and deep Tekla knowledge of Eneca’s team as well as their high-performance efficiency and always keen in continuous improvement, provided us an important support in our engineering process.

30.07.2021

Selecting the appropriate steel components is crucial for the strength and stability of your warehouse.

Steel Grades and Types

Different steel grades and types offer varying levels of strength, corrosion resistance, and cost. Commonly used steel grades for warehouse construction include ASTM A36, A572, and A992. Consult with your supplier to choose the best steel type for your specific needs.

Protective Coatings

Applying protective coatings to steel components can enhance their resistance to corrosion and extend their lifespan. Common coatings include galvanization and powder coating. These coatings provide a barrier against moisture and environmental pollutants.

Efficient Construction Techniques

Implementing efficient construction techniques can significantly reduce the time and cost associated with building a steel structure warehouse.

Prefabrication

Prefabrication involves manufacturing steel components off-site and assembling them on-site. This method minimizes construction time and reduces labor costs. Prefabricated components are often more precise and consistent in quality.

Modular Construction

Modular construction involves creating sections of the warehouse that can be easily assembled and disassembled. This approach allows for faster construction and flexibility in future modifications or expansions.

Designing an efficient steel structure warehouse requires careful planning and consideration of various factors, from site selection to technology integration. By leveraging the advantages of steel frame buildings and implementing efficient construction techniques, you can create a warehouse that meets your business needs while maximizing space and functionality. Whether you're expanding your current facility or building a new one, steel structure warehouses offer a durable, flexible, and cost-effective solution for your industrial needs.