Process & Piping Design

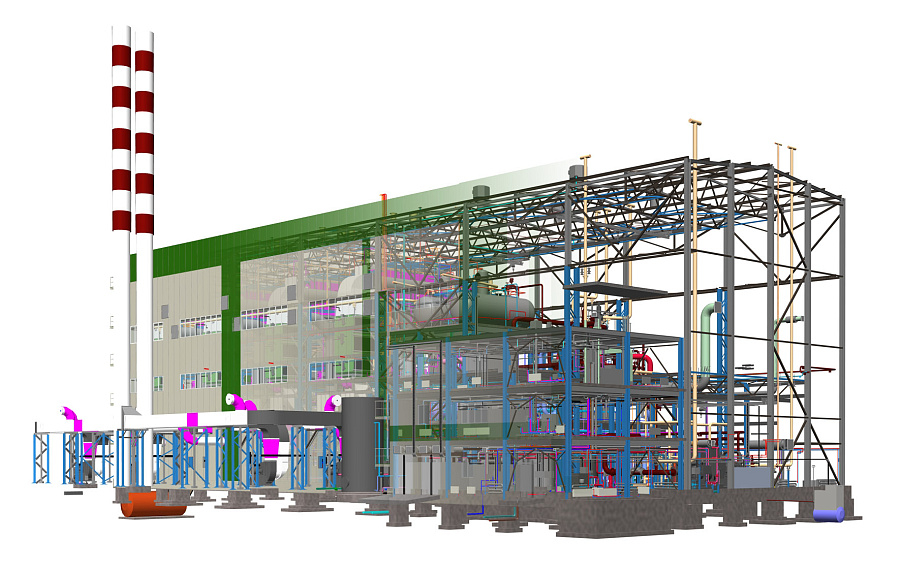

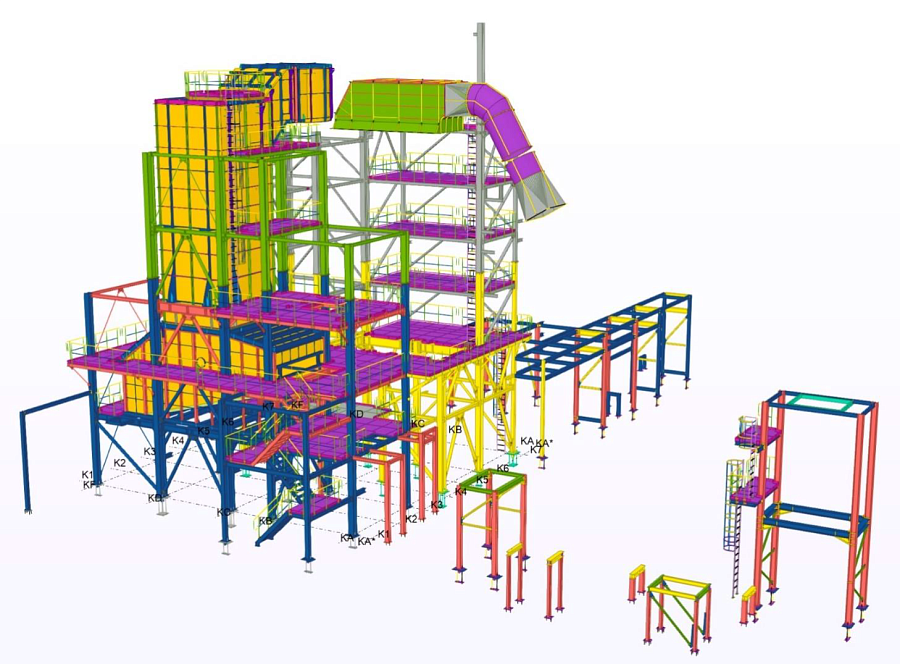

We develop process & piping solutions for combined heat and power (CHP) plants and power plants utilizing gas piston units, gas and steam turbines, as well as for steam, hot-water, and thermal oil boiler houses operating on various fuel types, including natural gas, diesel fuel, wood chips, industrial waste, and coal.

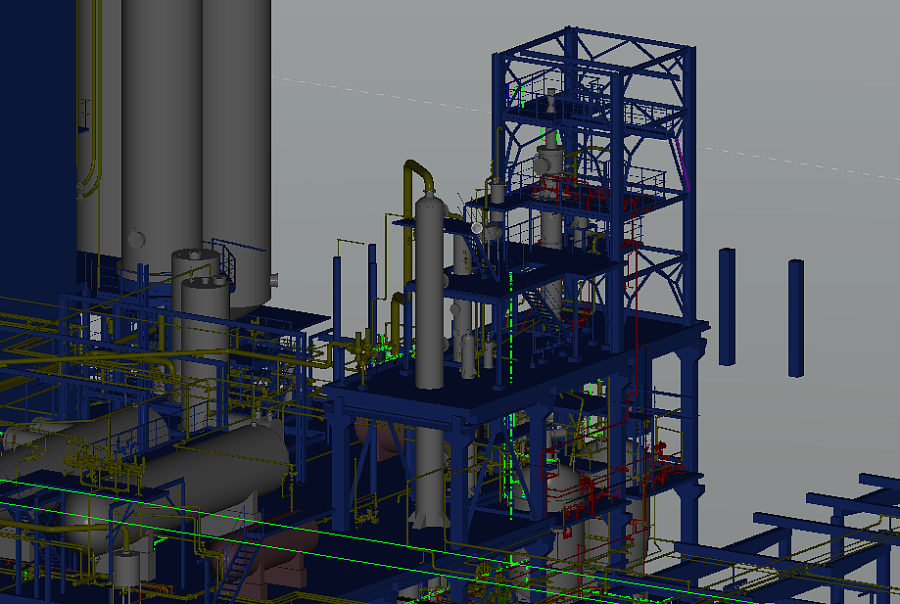

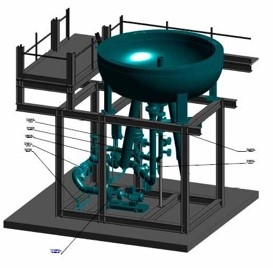

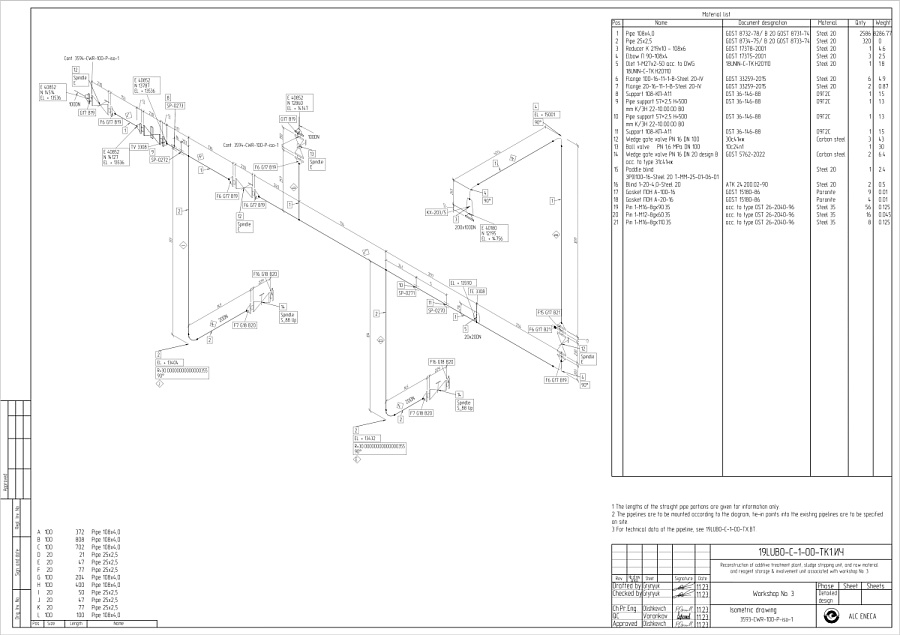

We also maintain a dedicated department specifically focused on piping engineering within the petrochemical and chemical sectors. We possess 10+ years of expertise in complex industrial piping design for production buildings (oil, gas, ammonia, carbon, chemicals etc.), tank farms, loading and unloading racks for petroleum and liquid ammonia, regional condensate stations, cleaning units, reactor, separator, decanter, oil pipeline, liquid ammonia warehouse with a capacity of 700 tons etc.

In addition, we are capable to provide structural design for piping supports that include selection of pipeline supports on the basis of calculations, 3D modeling of pipeline supports and workshopdrawings development.and sectors

The competence of our services allows us to work in a variety of sectors

ENECA, commissioned by Burger BK LLC, has completed design documentation for the modernization of a specialized building for the opening of the Burger King facility. ENECA, commissioned by ALS-FastFood LLC, under the project management of the engineering organization ProlaynTSK LLC, has completed design and estimate documentation for the modernization of the cafe premises for the opening of the Texas Chicken fast food chain facility.