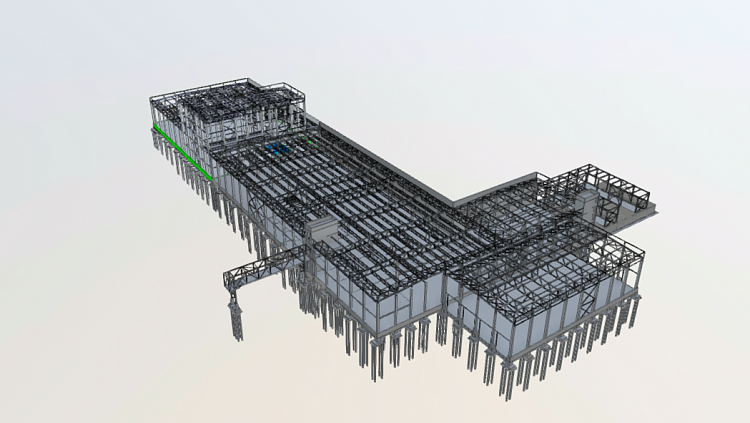

Butter and cheese factory

The project shows our expertise in complex BIM design across all stages, from basic to detailed design, covering a total area of 11,400 m2.

This project highlights our expertise in:

- Efficient collaboration: Seamless integration of architectural, structural, MEP, and process engineering disciplines

- Detailed planning: Comprehensive 3D models for accurate visualisation and construction planning

- Cost effective solutions: Optimised design for efficient resource allocation and budget management

Based on their experience, I can recommend Eneca.

We appreciate Eneca’s readiness to support us with BIM modeling on short notice, as well as their flexibility in providing the necessary resources to meet a strict deadline. All modeling was completed within two weeks, with a division into lots. Eneca’s specialists were always willing to take the time to discuss our concerns and accommodate additional requests.

Eneca’s strong expertise in Revit and professional experience in structural design enabled their team to quickly grasp Implenia’s high modeling requirements. The BIM model was developed in accordance with the 3D BKP Model guidelines and Implenia’s standards, ensuring compliance with parameter and element naming rules as per Baukostenplan Hochbau. Eneca’s detail-oriented and structured approach contributed to the creation of a high-quality BKP model aimed at automating the calculation of construction volumes and costs.

I am pleased with the quality of services provided by ENECA and can confidently recommend them to others in need of similar BIM modeling services.

The design process always requires flexibility and capability to think differently, and we were pleased to see Eneca’s readiness to support us and solve all the project issues together. When there was a need to do some quick revisions at a very late stage, Eneca's specialists performed them in a high qualitative and timely manner. The technical competence and deep Tekla knowledge of Eneca’s team as well as their high-performance efficiency and always keen in continuous improvement, provided us an important support in our engineering process.

30.07.2021